Considerations for Turn-key Generator Projects

Standby emergency generators are an excellent tool for many companies who want to maintain power when utility systems fail. When looking to install a generator, the scope often turns into a full turn-key installation project.

When the scope grows and you now have a full construction project on your hands, what are the things you need to consider? We’ll walk through some of the most critical principles and roadblocks we’ve seen with these generator installation projects.

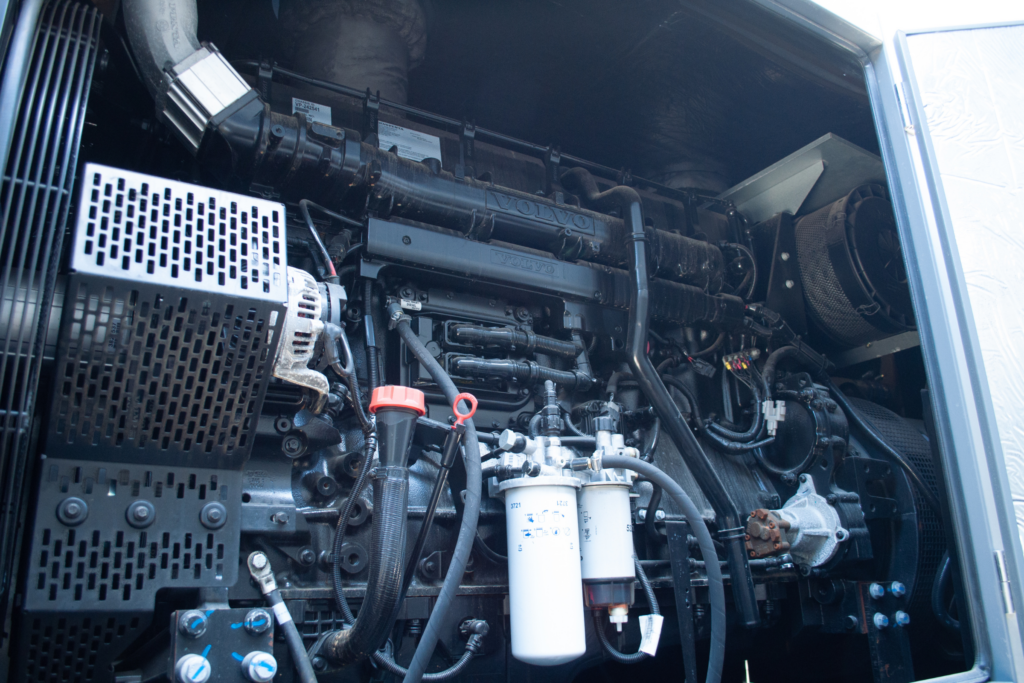

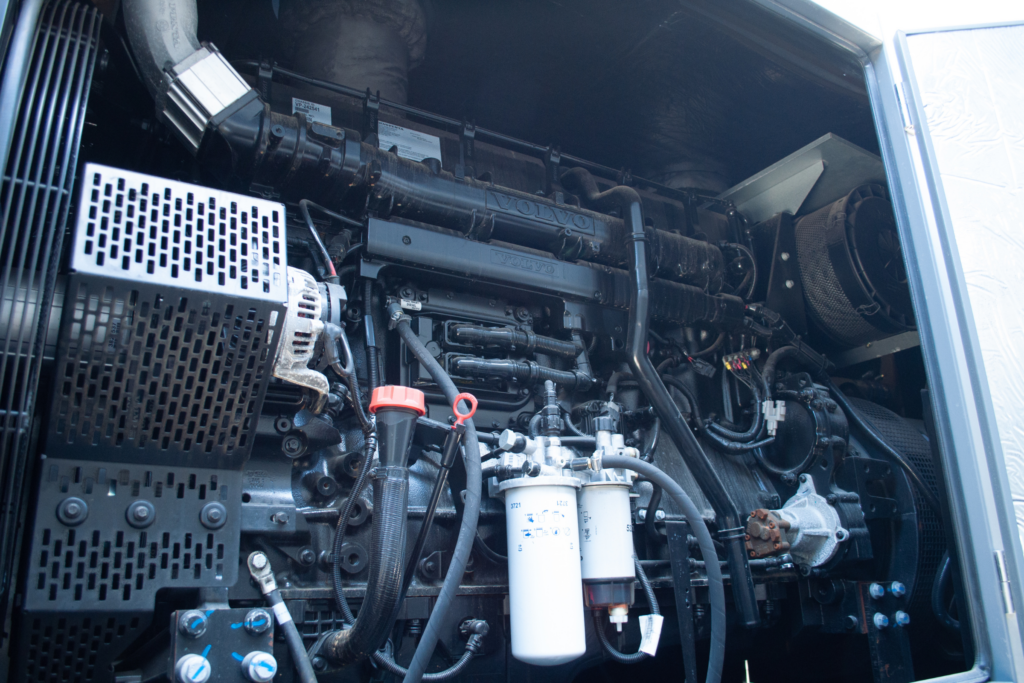

Generator Specifications

The most important part of your generator installation is the generator itself. If the generator doesn’t work as you need it to, then all your effort will be wasted. When specifying a generator, there are many things to consider.

Size

The generator needs to be sized large enough to handle the loads in the way you need. This is often measured in watts, kilowatts (kW), or kilovolt amps (kVA), which measure the energy the generator can output.

The sizing of the generator is based on the loads you need to run. Loads like lights, computers, servers, and motors must be considered. For motors, also consider how it is started (simultaneously or sequentially) so you know the initial draw.

Look at what loads need to be run together as well as the starting order. If multiple motors start at once, you need a more significant generator because of the initial pull. But if you start your motors in a sequence, you can often save money and downsize.

One great tool to help calculate these loads and what size generator you need is Generac’s Power Design Pro. This program walks you through putting in your loads and the sequence to calculate the required variables.

Voltage

What voltage does your facility need to run? It could be 120V, 240V, 480V, or above 1000V. For lower voltages, is it single- or three-phase? Using a generator with the wrong voltage could cause your system to malfunction or fail.

Fuel

The fuel that you will run the generator on is essential to specify. Diesel is a common option when there needs to be fuel stored on site. Natural gas tends to run cleaner and requires less maintenance in the long run; although it may require a higher initial cost in larger generator sizes, it can often win out when looking at the total cost of ownership. Propane is often the necessary fuel in remote locations.

When looking at what fuel you will use to power the generator, also look at how you would replenish that fuel and what costs the fuel might bring. There are upfront costs to consider, whether running gas lines or purchasing tanks, as well as maintenance costs, such as diesel fuel polishing, testing, and refueling. Diesel is also prone to wet stacking, which can cause generator performance issues.

It also helps to look at how you would keep the generator fueled and running in case of a long-term outage, such as bringing in diesel fuel by truck.

Sound

The engine, exhaust, and generator components make noise, similar to a car or large truck. Some generators are in areas surrounded by other heavy industries where noise isn’t a concern. For a generator at a pump station in the middle of a neighborhood, however, the weekly generator exercise and any other needed use could lead to issues for the surrounding environment.

Some generators are placed inside a building, often in a basement or on a roof. In these cases, the noise may affect the rooms and floors nearest to it, which may need to be mitigated.

Specifying a set decibel or dBA can help ensure that your generator has as little impact on the surrounding environment as possible. The system may mitigate this by building a level of sound suppression into the enclosure, constructing sound walls, or creating physical distance.

Need more help?

Get advice from industry-leading experts who can answer any questions you have and give you different options to solve your problem.

Temperature

Just like trucks that struggle to start on a cold morning, you should consider what problems temperature might lead to on your generator. Consider adding block heaters if you have a generator going into a cold environment. If excess heat is an issue, consider what cooling may be necessary. Block heaters and proper heat exhaust are the most common temperature control methods we’ve seen used to help with these issues.

We’ve also seen problems in the past where not enough clearance is given to the generator’s exhaust. This leads to warm exhaust air recirculating into the air intake, overheating the engine and leading to alarms, shutdowns, or damage.

Weather Protection

If your generator is placed outside, you need to be able to protect it from the elements. You may encounter rain, wind, snow, or other common issues. Similar to temperature, these factors are dealt with quite often and are easy to deal with if they’re considered upfront. Increasing the enclosure’s protection level helps keep the generator running longer.

Elevation

While considering your environment, determine the elevation your generator will be operating at. Higher elevations have thinner air, which can affect the cooling and efficiency of your motor. A generator’s engine may need to be derated (or oversized) to get the same output at a higher altitude.

Seismic

Seismic requirements may also be a factor in some areas. If there is a seismic mitigation requirement, extra thought must go into the generator’s design. You may see different mounting to the ground, additional clearance, or other considerations.

NFPA 110

NFPA 110 is the National Fire Protection Association standard 110 for Emergency and Standby Power Systems. In some situations, a generator may be deemed “life safety.” This means an outage would risk the lives of those whose power was lost. This is typically associated with healthcare facilities such as hospitals, surgery centers, and assisted living facilities.

When this is needed, additional requirements include on-site fuel storage, docking stations for backup during maintenance, and load banking during maintenance. It can also include working with authorities having jurisdiction (AHJs) in order to know what the specific local requirements and interpretations will be.

Electrical

Once the right generator is specified, you need to consider how it will interact with your existing electrical system. The purpose of a generator is to supply electricity, which makes this step a crucial part of your project planning. As you look at electrical changes, make sure to evaluate what permits are needed in your area for the work you do.

Wire and Conduit

Wire and conduit are how you will get the electricity from your generator to your system. If there isn’t a plan for how that will be prepared and sized appropriately, your generator will never get the power to the devices that need it to operate. Accurate one-line and electrical diagrams along with field verification will help to make sure that everything has the backup power it requires.

VFD and RVSS Interactions

Variable frequency drives (VFDs) are a common tool to control the speed of motors. You can learn more about VFDs and how they work here. Reduced voltage soft starters (RVSSs) are also electrical equipment that can help a motor start in a more controlled manner, and both are great tools to reduce the requirements of a starting motor.

VFDs create harmonics and are often accompanied by capacitors and other devices, which can cause power factor issues with a generator. Evaluate what controls and devices like these are on the load side of the generator that may cause problems. Look for VFDs, soft starters, capacitors, and other devices that may affect harmonics, power factor, or other issues.

The Power Design Pro tool is excellent at helping to calculate how harmonics and other loads can affect the generator and what sizing would be changed based on motor starting methods.

Automation and System Integration

If you have building automation or a SCADA system, you will want to ensure the devices needed to make the generator compatible are included. Even if they are, you need the connection to the generator to ensure it can communicate. Make sure that controls are run to the generator, and also account for Wi-Fi, internet, Bluetooth, or any other needed technology.

Docking Stations

If your life safety generator is unable to run due to maintenance or repairs being done, NFPA 110 will require that you still have back up power during the time the unit is down. The most common way we see this addressed is through a docking station. This allows for a portable generator to be connected and back up your facility during maintenance or repairs. Make sure to account for this and comply with those requirements.

Civil

Civil requirements are important to ensure that your generator installation is safely designed and will remain stable and reliable for as long as possible. As you look at civil changes, remember to determine what permits need to be obtained.

Concrete Pads

Industrial generators should be installed on a level, stable, strong concrete pad. Even mobile generators should be placed somewhere they are stable and secure. As you design a concrete pad, consider the generator’s weight and placement. Look at the specifications and drawings, so that conduit and other stub-ups are located appropriately. If you have remote fuel storage, consider how that fuel delivery system will affect the pad.

With the pad, also take into account maintenance and walkways. You may need to extend the pad past the edge of the generator enough that technicians and maintenance personnel have a stable ground to work from. Suppose you have a tall generator, or it’s on top of an elevated diesel fuel tank: you may also need a walkway installed so that the filters, controls, and other necessary components are easily accessible for maintenance or troubleshooting.

Lastly, consider how the generator will be placed on the pad. Will a crane or forklift be needed to place the generator? Will it be able to access the pad safely and accurately?

Walls, Fences, and Bollards

Walls may be required in some situations. When dealing with sound requirements, you may need a sound wall to reduce the dBA in specific directions. There may be local ordinances or requests that the generator is hidden from view by a wall or fence, or you might just need to restrict access to the generator.

If your generator is surrounded, evaluate how you can still access the generator for work. Make sure that the keys or codes are accessible in case emergency access to the generator is needed.

With walls and fences, you also need to consider how much space the generator needs to function correctly, including exhaust venting, room for air intake, space to refuel, and other requirements. Leave enough space for electrical and OSHA requirements on clearance, plus what is needed to safely and efficiently maintain or evaluate the generator.

One common way to protect the generator while maintaining accessibility is to surround it with safety bollards. These may be required for specific uses and can vary in color, withstand ratings, height, and other requirements. Verify that they don’t interfere with the generator’s access if installed.

Secondary Containment

Double-wall fuel tanks accompany most diesel generators. In some cases, secondary containment could be required, and we’ve seen this often required for sites near rivers, streams, or other environmentally-sensitive locations.

Secondary containment is usually built with cement, metal, or plastic walls surrounding the generator. As with other civil considerations, ensure appropriate access for maintenance and compliance to relevant standards.

Safety

Generators are essential to maintaining safety on a site, but you also should consider how to keep those safe who might be near the generator.

Emergency Stop

An emergency stop, also known as an e-stop or kill switch, is a button that can be used to shut down the generator in an emergency. These are typically easy to see and should be labeled clearly in accordance with electrical, local, and site requirements. They should be easily accessible. If you build a wall or fence around your generator, it may need to be located in an unlocked location, such as located near your transfer switch or other controls.

Often we see that emergency switches are protected from accidental presses while still being easy to access in emergencies. These may include unlocked covers or “break glass” style setups. When an e-stop is needed, coordinate with what local and other regulations require.

While looking at your emergency stop and labeling, you should also look at your ATS. Is it clear where this is to anyone working on the generator? You may consider posting a sign near the generator where to find the ATS if it’s not within sight and obvious.

Warning Signs, Labels, and Marking

Depending on electrical, local, OSHA, and site requirements, anything that produces noise, has moving components, or deals with electricity may need to be labeled. Consider what size the labels should be and where they should be posted. You may also need to mark the ground, wall, or fence surrounding the generator or control approach areas and other distances that should be observed for safety.

Need help with a generator install?

With our experienced team of engineers and technical specialists, we can help you every step of the way to install your generator and maintain it afterward to ensure your generator runs at its best.

Commissioning

To verify that a generator installation project will have the desired results, you should consider how you commission the generator system.

Commissioning Plan and Warranty

Commissioning plans depend on the manufacturer and who you bought the generator from. If you buy from a supply house, you may need a third party authorized by the manufacturer to commission and start up the generator. If you buy from a generator manufacturer’s direct distributor, there is a good chance they also have a service team who can complete this work.

Authorized commissioning is usually necessary for the warranty on the generator and ATS to be registered and valid. In many cases, a generator manufacturer will require that their authorized team be there for the first time the generator is run, so be careful to read through the warranty requirements.

Verify that you have appropriate access for the commissioning. Not only do you need the space to do it, but you also need to make sure that the commissioning technician has needed keys and codes, or has someone to supply those on site.

Suppose you are conducting a load bank with the start-up, whether for NFPA 110 requirements or simply as a best practice: verify that the system is ready for that and appropriate time is allocated. In order to comply with NFPA 110, load banks often take hours. Your chosen factory-authorized commissioning team will be able to walk you through what is needed based on your circumstances.

Ongoing

As you plan for a generator installation, you should look ahead to what the ongoing use of the generator will look like. The turn-key installation is only the beginning of the generator’s life at your facility, so you should be prepared for the long term.

Maintenance Cost and Commitment

When evaluating generators, look at the cost of maintaining them. Evaluate the manufacturer’s suggested maintenance schedule and what parts will be needed periodically. This includes oil filters, air filters, batteries, and other components. You will want to look at fuel polish, refueling, and similar costs. These will typically be lower on a natural gas generator than a diesel system as you would have reduced fuel maintenance needs.

Depending on NFPA 110 requirements and other preferences, you may also need to account for load banking periodically. This will help to prevent wet stacking, especially in diesel generators.

Look at the local support that can supply this maintenance, whether it’s your team or a local service company. The distributor for the manufacturer often has a factory-authorized team locally who can help. It’s important to consider how many local, qualified, 24/7 technicians are available to support problems.

Reliability

When you look at a generator system, look at the reliability. Most manufacturers will have data on a system’s mean time between failures (MTBF), which can indicate reliability. You may also want to look at the reliability of other integrated systems, such as your main utility or the fuel supply.

Monitoring Capability

When looking at the long-term usability of a generator, analyze how easy it is to monitor and detect problems with the generator. Determine whether it can integrate into the systems you currently have existing. What capabilities does the generator offer if you need emails, texts, or audible alerts? How easy is it to use and diagnose problems through the controller?

Redundancy and Additions

When you design your system, consider what happens in a failure. Is there redundancy? How safe is your system if you have more capacity than you need or just have generators with built-in redundancy?

We like to use Generac Gemini generators as they have two 500kW engines making up a total of 1MW of power, meaning a complete engine failure still leaves you with 500kW of power to back up your most critical loads. These can also be paralleled together to add more capacity if needed. This provides a high amount of redundancy and the smaller engines often come in at a competitive price point.

Also, consider future growth. Can the generator you install be paralleled or added to later if your system needs to grow? What would that look like?

A generator turn-key installation can be a big project with many components. While there’s a lot to consider, breaking it down into sections can help to plan the different stages.

As always, the experts at Energy Management Corporation are happy to talk through your specific project and needs. Whether it’s a complete turn-key installation, a retrofit, or some other generator project, contact us to discuss your questions.

Want to learn more about our generator service?

As always, the Experts at Energy Management Corporation are happy to talk through your specific project and needs. Whether it’s a complete turn-key installation, a retrofit, or some other generator project, contact us to discuss your questions.

Marketing Manager

Tyler is a marketing manager focusing on VFD, motor, and generator applications. In the past he’s worked in sales for these same products. He is a proud graduate of Utah State University and enjoys spending time with family and friends.