Common causes of generator failure and what to do about it.

Emergency standby generators are an essential piece of equipment for many businesses as they keep vital processes up and running. Some areas, like Las Vegas, are prone to a big issue for generators: heat. If you’re looking at buying, installing, or maintaining a generator in Las Vegas, there are several things to consider to ensure that your generator lasts longer and works when needed.

What causes a generator to overheat?

Several issues could cause a generator to get too hot. These range from internal to environmental problems, but all overheating matters should be examined.

Generator sizing

If your generator is consistently overheating, you may want to evaluate whether it’s large enough for the demands. A generator may initially be correctly sized, but as new motors or other loads are added, the generator may not be enough. You may have also changed how you bring your loads up, bringing more on at once and overloading the generator.

Look at elevation. Las Vegas is about 2,000 feet above sea level; many surrounding areas may get higher. The air becomes thinner when the elevation increases and many components struggle to cool themselves. Make sure your generator was properly de-rated (or upsized) for the elevation.

Looking for more sizing information?

More information is never a bad thing. If you would like to learn more about sizing generators, check out our Generator Sizing webinars.

Ambient conditions

The next most obvious place to look is the ambient conditions. Is the temperature warmer than what was initially expected? Is the generator not in the shade that was expected? Is there more humidity or some other issue? You may even want to evaluate the paint color. If the generator has been repainted or is a darker color, it may attract more sun and heat than was initially planned.

Environmental contamination

Desert installations like Las Vegas are likely to run into environmental issues that can make a generator run hot. Dirt, dust, and debris on components and the enclosure can cause problems. When there is contamination, the generator and its components don’t dissipate heat the way they’re designed to. Keeping your generator clean and planning for locations that stay cleaner can help it to run cooler.

Electrical issues

Generators are made to produce electricity and therefore, have many electrical components. If there’s damage or a failure in any of those components, you may get warps, hot spots, or other issues. Verifying the health of the rotor and other issues can help identify the cause of heat. We recommend having a rotor inspection done by a local expert, and they can tell you whether a repair, rewind, or replacement is needed.

Cooling system issues

Rather than producing too much heat, sometimes the issue is that the generator isn’t correctly cooling itself. Fans, blowers, filters, and exhaust systems must be inspected for damage or blockages, and any of these could prevent proper airflow that would cool the generator.

One issue we’ve seen too often is that the needed clearance around intakes and outlets/exhausts is not accounted for. We’ve seen generators installed under ceilings with not enough clearance, which causes the hot exhaust to cycle back into the cool air intake. In the best cases, this leads to an alarm that prevents the generator from running. In the worst case, it could lead to damage or failure which becomes a more significant issue to fix.

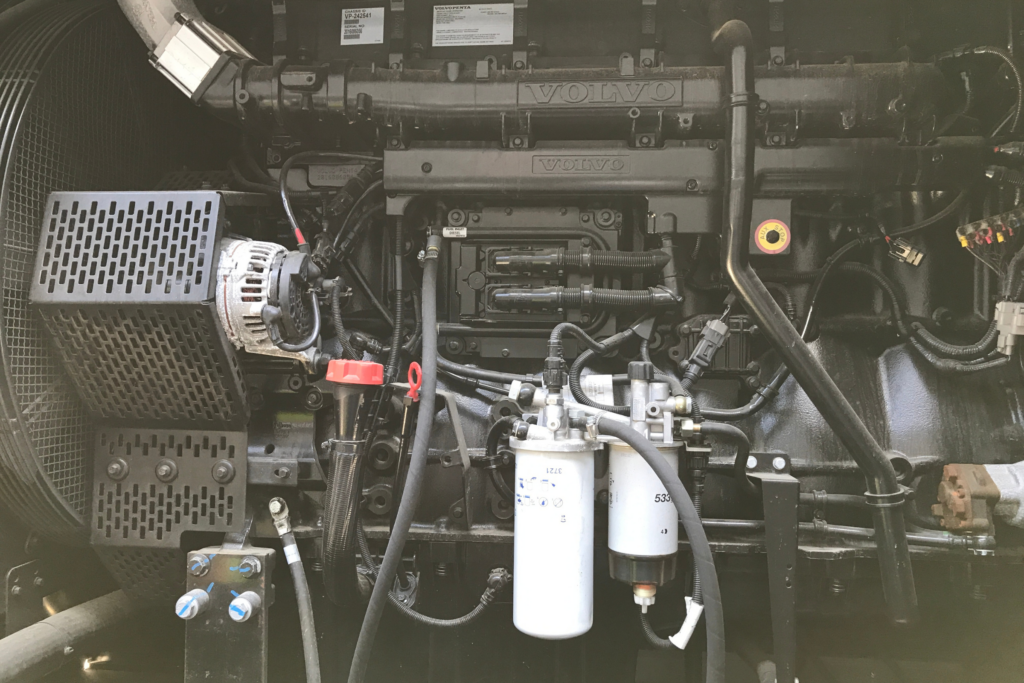

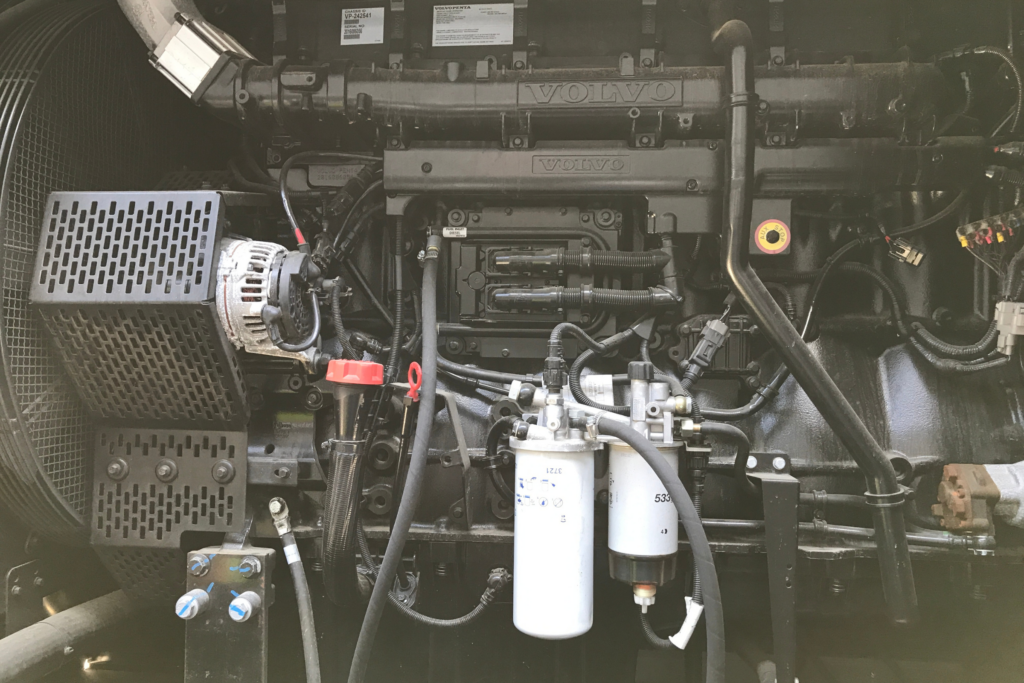

Coolant and oil issues

Generators have internal systems to control the engine’s temperature and components. These coolant and oil systems have pumps, reservoirs, hoses, clamps, and other parts that can fail. These parts, as well as fluid levels and cleanliness, should be regularly checked.

Monitoring issues

If your generator is set to monitor for heat, verify that the monitors and sensors are functioning correctly. If the temperature is being misread or not being communicated correctly, the other systems may not receive the message to begin cooling.

How do you fix heat issues?

Once you’ve identified that your generator is overheating, what do you do about it? The key to fixing heat issues is to identify and correct them before they get too severe and cause damage, leading to more serious repair or replacement.

Make sure the generator exercises

Generators should often exercise to make sure that they are operating correctly. These exercises are often where overheating alarms arise, giving a chance for corrective action to occur. They also ensure that all components move regularly and work as they should.

Conduct thermography evaluation

Using an IR camera to take thermographic images helps to identify hot spots and other issues. These can alert you to the issues discussed above and help you plan for potential repairs or failures.

Conduct preventative maintenance

Every site with a generator needs a clear, routine maintenance schedule. We recommend two services per year as a minimum. Every year you should change oil, check hoses and belts, and evaluate components. When replacing oil and other filters, write the date of the change on the filter. Record all work done and document conditions with pictures.

Between each service visit, you should have an expert come by to inspect the generator. Generator technicians should inspect belts for wear, hoses for cracks, clamps for tight fits, fans for proper operation, and the overall generator condition and cleanliness. A site evaluation should document any changes that might affect the heat. These could include items blocking air intake clearance, other construction that might change the load, and anything else notable.

If you have many sites around Las Vegas, the state of Nevada, or even farther reaching, develop a geographic route that makes sense. Even though it’s maintenance, you still need to plan for the oil, filters, and other components you need to bring. This is where it often makes sense to hire a company like Energy Management Corporation to help. We can plan these routes with other local generators and conduct other on-site services. Combining a generator maintenance visit with VFD maintenance, motor vibration testing, or other services saves travel time and expense.

Want to learn more about our generator service?

Beat the heat! Don’t let your generator fall into disrepair. Let EMC help you. Call us at 800-595-5315 or connect with our expert technicians here:

Marketing Manager

Tyler is a marketing manager focusing on VFD, motor, and generator applications. In the past he’s worked in sales for these same products. He is a proud graduate of Utah State University and enjoys spending time with family and friends.