How to know if you should repair or replace your electric motor

In the event your motor fails and causes unscheduled downtime, you need to very quickly have an idea of whether you are about to repair or replace said motor. Cost, availability of parts, and the overall effects of downtime on your business will all play a role in this important decision. In this article we will take a look at a few of the most important factors that should influence your decision.

What Caused the Failure?

Before you consider repairing or replacing your motor, you need to identify the root cause of the failure. If the failure was caused by an issue with your driven application, or by a failure to perform routine maintenance, you can make the proper adjustments within your own walls to prevent the failure from happening again. If the failure was caused by a defect from manufacturing, you can inform your motor shop and make sure the appropriate steps are taken to correct this mistake.

Considerations

Before making the decision to repair or replace your motor, you need to ask yourself a few questions in order to make the best decision for your application:

- Does the failed motor best fit your application?

- Has a catastrophic failure occurred?

- I.e. Is there damage to the stator core and laminations, windings, rotor core, rotor bars, rotor end rings, shaft and bearings, or end brackets?

- Will purchasing a brand new motor cause extended downtime?

- What is the condition of all inside and outside parts?

- How old is your motor?

- What is the cost of repairs vs. replacement overtime?

- Is it an EPAct or NEMA premium motor?

- Are any other parts severely damaged?

Repair

If the answers to the questions above match those found below, repairing your motor may be the best option for you:

- The failed motor is the best fit for your application.

- Catastrophic failure has not occurred.

- Purchasing a brand new motor will cause extended downtime.

- The overall condition of your motor is ok.

- Your motor is not very old.

- The cost of repairs is less than the cost of replacement, overtime.

- It is an EPAct or NEMA premium motor.

- No other parts are severely damaged, besides the part that caused the failure.

If you are not sure about the answers to these questions, it is crucial to have a good relationship with your motor repair shop. Having your repair shop give you an estimate on repairing vs. replacing your motor, and knowing they will give you honest and correct feedback on the status of your motor, will help you make the best decision for your application.

Replace

If your answers to the questions found in the “Considerations” section match those found below, replacing your motor may be the best option for you:

- The failed motor is not the best fit for your application.

- Catastrophic failure has occurred.

- Purchasing a brand new motor will not cause extended downtime.

- The overall condition of your motor is not great.

- Your motor is very old.

- The cost of repairs is more than the cost of replacement, overtime.

- Your motor is not an EPAct or NEMA premium motor.

- Many parts are severely damaged.

Energy, Efficiency & Life Cycle Costs

To help make a decision on which route to take in regards to replacing or repairing your motor; you should calculate the annual energy cost, life cycle costs, and efficiency of your existing motor vs. a replacement motor.

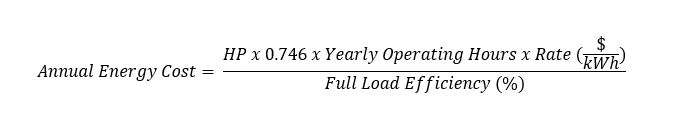

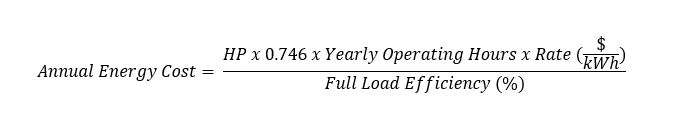

To calculate the annual energy costs, follow this equation: (Assumes 100% load):

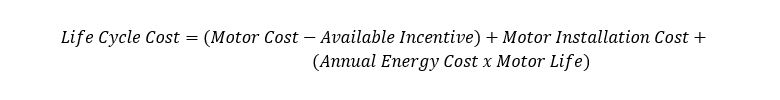

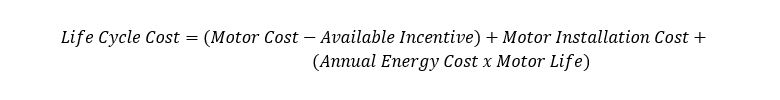

To calculate the life cycle costs, follow this equation:

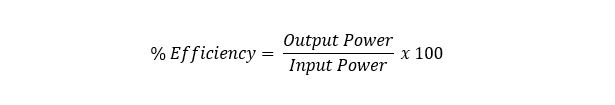

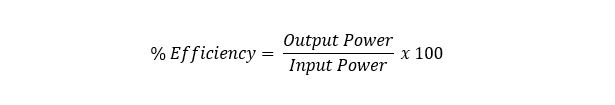

To calculate efficiency, follow this equation:

Final Considerations

If you are planning to replace your motor, make sure that your new motor outshines your old motor in the performance areas measured by these equations. There is no reason to sink thousands of dollars into a new motor, if it doesn’t perform better than your current motor.

This article is based off our Webinar: Getting the Most out of Your Electric Motor

Got More Motor Questions? We Can Help!

Call 800-595-5315 Or Connect With Our Expert Technicians Here:

Other Articles

- Critical Spare Planning

- The Three Most Common Externally Caused Motor Failures

- Remedies For Common Motor Winding Failures

Director of Motor Service

Josh has over 20 years of experience in electric motor repair, as well as welding and machining. He is also an expert mechanic. He is in charge of our motor service centers in all 5 EMC locations.

Your article does a great job of breaking down the different types of electrical services and explaining when they might be needed.

I also appreciated the emphasis on safety and the need to hire a licensed and qualified electrician for any electrical work.